Course overview

You study core modules that provide you with the relevant learning to further your career, along with an optional module that enables you to explore a specific area of mechanical engineering.

Course details

Course structure

Core modules

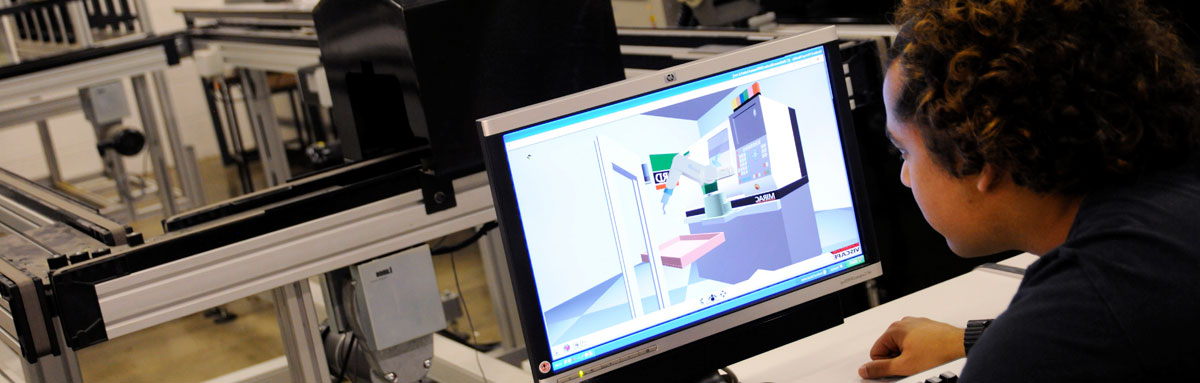

CAD/CAM and Product Developments

This module provides knowledge of time compression technologies to enable design and delivery of innovative products and reduce time to market. It includes a study of rapid prototyping and production development techniques alongside a review of collaborative product development and concurrent design engineering strategies using 3-D modelling to minimise manufacturing lead time. You are introduced to various software packages; you are encouraged to take a critical view of these packages and consider their integration with other systems.

You investigate an area of engineering and work independently to a level recognised to be at the forefront of the discipline. The topic can be in the form of a research project or a design project. Key skills in research and in knowledge application and creation will be developed through keynote lectures and self-managed independent study. You are required to demonstrate the capacity for a comprehensive and objective analysis, and for developing innovative and constructive proposals for the solution to the project topic.

This module provides practical experience of using commercially available finite element packages. The application of the method is demonstrated using a number of case studies. You are encouraged to use the technique as an extension of your standard text books in solving design and manufacturing problems.

Engineering Design may be defined as an interactive decision-making process that has as its objective the creation and optimization of a new or improved technical system for the fulfilment of a human need or desire, with due regard for conservation of resources and environmental impact.

This module develops the comprehensive theories and the principles of Mechanical Design and applies them to the design and analysis of realistic engineering problems analytically and/or computationally.

Specific areas of study include:

- advanced principles of design and stress analysis

- design of a mechanical drive

- design details and other machine elements

- experimental stress analysis

Lectures introduce each major topic on the module emphasizing both the conceptual and theoretical development and their applications to realistic engineering problems, through worked examples. Tutorials and seminars are used primarily for you to practice and to provide feedback. Laboratory session is used to investigate the experimental stress analysis and develop a deeper understanding of the theory and principles.

Assessment is by three in-course assignments.

This module demonstrates how to benchmark an organisation and introduces you to the concepts of key performance indicators, total quality management (TQM), six sigma, total productive maintenance (TPM) and supply chain management. You learn the manufacturing assessment methodology based on data provided in a benchmarking case study. Topics covered in TQM, TPM, and supply chain management enable you to plan activities, which improve quality programme maintenance planning and supply chain integration for an organisation and move that organisation towards sustainable competitive advantage.

You will investigate how the role of the engineer is becoming more focused on serving society as well as industry and to recognise the impact of engineers’ decisions on society and the environment.

As engineers of the future, you will need to have a sustainable worldview, acknowledging international, cultural, and diversity issues in society. In addition, you will also be expected to solve complex problems with consideration for multi-perspective views, long-term effects, risk, and the impacts of decisions on society.

This module will examine the key topics surrounding sustainability in the context of engineering applications across a range of disciplines and key future challenges such as energy, transport, and construction.

The subjects will be taught through a combination of lectures and seminars. Lectures will develop key concepts and knowledge. Seminars will allow more focused examinations of important issues and approaches.

and one optional module

This module develops a universal framework of mechanical principles that applies to all materials and integrates classical treatment of fluids and solids with more recent developments in rheology. The theoretical development is made concrete through extensive use of examples drawn from real world applications to ensure it is thoroughly grounded in current industrial practice.

Tutorials provide the opportunity for you to become fluent in the manipulation of the appropriate notations, principles and laws; and to develop competence in the application of these principles to a broad range of real world examples and Case Studies.

This module considers typical hardware and software involved with automated machinery and production processes. It shows you how machines can be integrated into flexible cells and flexible manufacturing systems and, when linked with appropriate production management software, into computer integrated manufacturing systems.

Modules offered may vary.

How you learn

You learn through lectures, tutorials and practical sessions. Lectures provide the theoretical underpinning while practical sessions give you the opportunity to put theory into practice, applying your knowledge to specific problems.

Tutorials and seminars provide a context for interactive learning and allow you to explore relevant topics in depth. In addition to the taught sessions, you undertake a substantive MSc research project.

How you are assessed

Assessment varies from module to module. The assessment methodology could include in-course assignments, design exercises, technical reports, presentations or formal examinations. For your MSc project you prepare a dissertation.

Entry requirements

You need a first degree equivalent to at least a UK second class (2.2) honours degree. Acceptable engineering degree subjects include mechanical, aerospace, aeronautical, manufacturing, production and mechanical systems.

Students with a degree awarded outside the UK must also meet the University's minimum English language requirements.

International applicants who need a student visa to study in the UK should check our web pages on UKVI-compliant English language requirements. The University also provides pre-sessional English language courses if you do not meet the minimum English language requirement.

For general information please see our overview of entry requirements

International applicants can find out what qualifications they need by visiting Your Country

Employability

Career opportunities

Mechanical engineers typically secure employment in structural engineering, research and development, automotive engineering and design, the aerospace industry, manufacturing, processing and chemical industries as well as management positions.

Information for international applicants

Qualifications

International applicants - find out what qualifications you need by selecting your country below.

Select your country:

Useful information

Visit our international pages for useful information for non-UK students and applicants.

MSc Mechanical Engineering graduate

MSc Mechanical Engineering graduate